Phone Lines down - 28th June 2023

Simon Miller • June 28, 2023

Wednesday 28th June 2023 - we are having issues with our phone lines, please use email to contact us. It seems this is a wide spread issue.

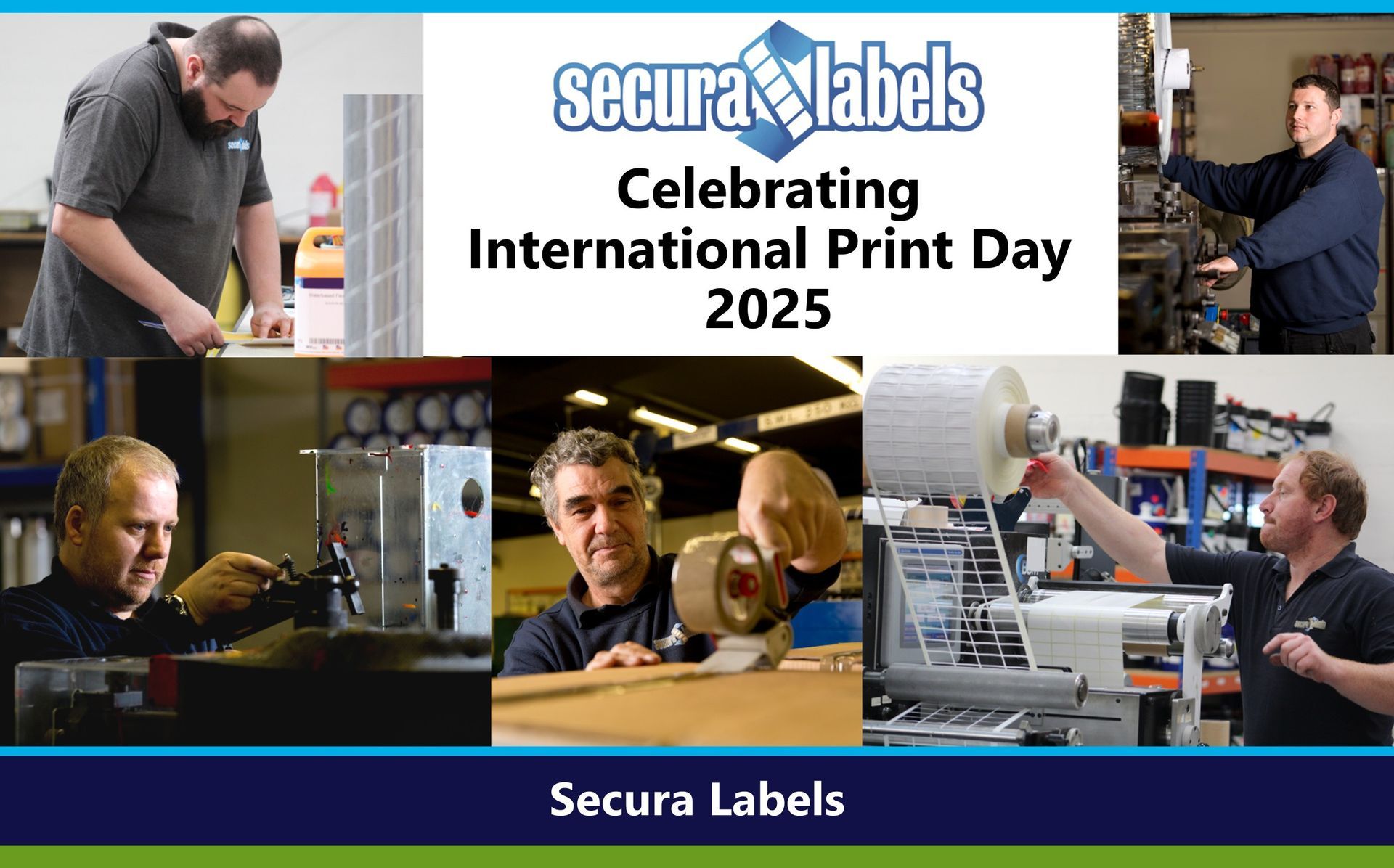

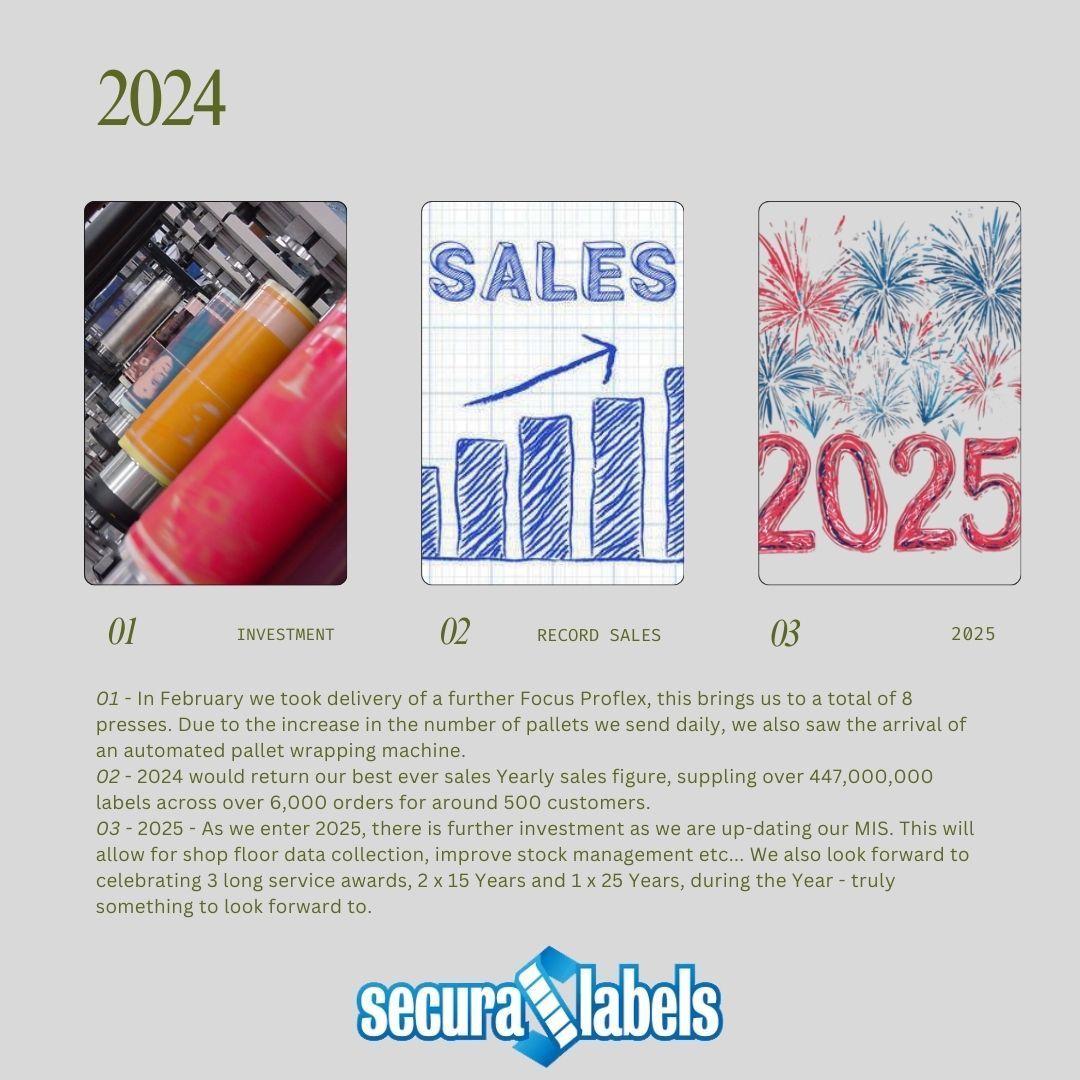

2024 A little look back at 2024 and into 2025 - Further press investment, as a further Focus Label Machinery Limited Proflex arrived in February, this 4 colour machine, our first fitted with LED curing, will have automated finishing through one of our turret rewinders. Investment continues in 2025 as we are currently installing a new MIS system, which will allow shop floor data collection, improved stock control etc... We also look forward to celebrating some long service awards during the Year. With much achieved in 2024, we are looking forward to a further successful 12 Months!

Cutters / dies, we carry a vast library of cutters, 1,000`s in fact. Most of these are magnetic, thin metal sheets, attached to magnetic bases, which means that many are interchangeable across our machines. We do still use and order "solid" cutters, this can be for a range of reasons, one of our cutter suppliers, Kocher & Beck, offer a view on the Pros and Cons between Flexible and Solid cutters here . Once a cutter / die is made it is not possible to alter, a new one would be needed to change any aspect, corner radius, gap between labels etc..... It should also be noted that cutters made to cut certain materials, say direct thermal paper, may not be able to cut a PP. This is much like your kitchen knives, a butter knife would not be used for slicing bread for instance, like our cutters, cutting angles, even material, could be different. We do always try and order a cutter to cover as wide a range of material as possible, but sometimes this is not possible. Cutter setting is one of the most critical aspects of our production, getting the die "strike" just right can be the difference between a job running well and not. Too heavy a "strike", and we risk cutting through the backing paper, giving you, the user, issues. Not heavy enough and we will have issues with stripping the waste matrix and not be able to run at an acceptable press speed. Cutter care also plays a part here and we expect our operators to maintain a high standard of care. All of our operators, indeed all of our staff, have been through the Kocker & Beck Training Academy where they learned various aspects of cutter setting, care of cutters, alongside seeing how a cutter is made. We are always open to visitors, so if you wanted to find out more about cutters, give us a call and arrange to drop in. Common Questions - "I want to change the gap between the labels, I wont need a new cutter will I?" Once cutter is made, it is not possible to change any aspects, so to change a gap or corner radius would mean a new cutter. "I have just order some labels on semi gloss paper, but you are quoting a new cutter for a PP job of the same size, why? " Much like your kitchen knives, a butter knife would not be used for cutting bread, a cheese knife not used for preparing vegetables. Cutting angles and even material could be different for best cutting a PP compared to a paper. "Can I have any size label, any shape?" Within reason yes, our current smallest cutter is 5mm dia, our largest 312 x 416mm (this the largest we could produce), but you can have any size. As for shapes, we can, or at least the cutter makers can, make quite complex shapes, the biggest factor we need to consider, is can we strip the waste from a very complex shape? "How much time does a new cutter add to my order?" Usually, a new cutter would be with us in around 48 hours, so there should be no major impact on delivery times. "Why can I never get a simple gap of say 3mm, why is it 3.4mm?" Our machines, and so cutters, work based on imperial measurement, 1/8" gearing. This does mean that cutters / print cylinders need to fit into increments of 1/8", which results in the gaps it does. "How heavy are the cutters?" They can be very heavy, 25kg +, but all of our machines are equipped with lifting equipment to lift the cutters in and out.