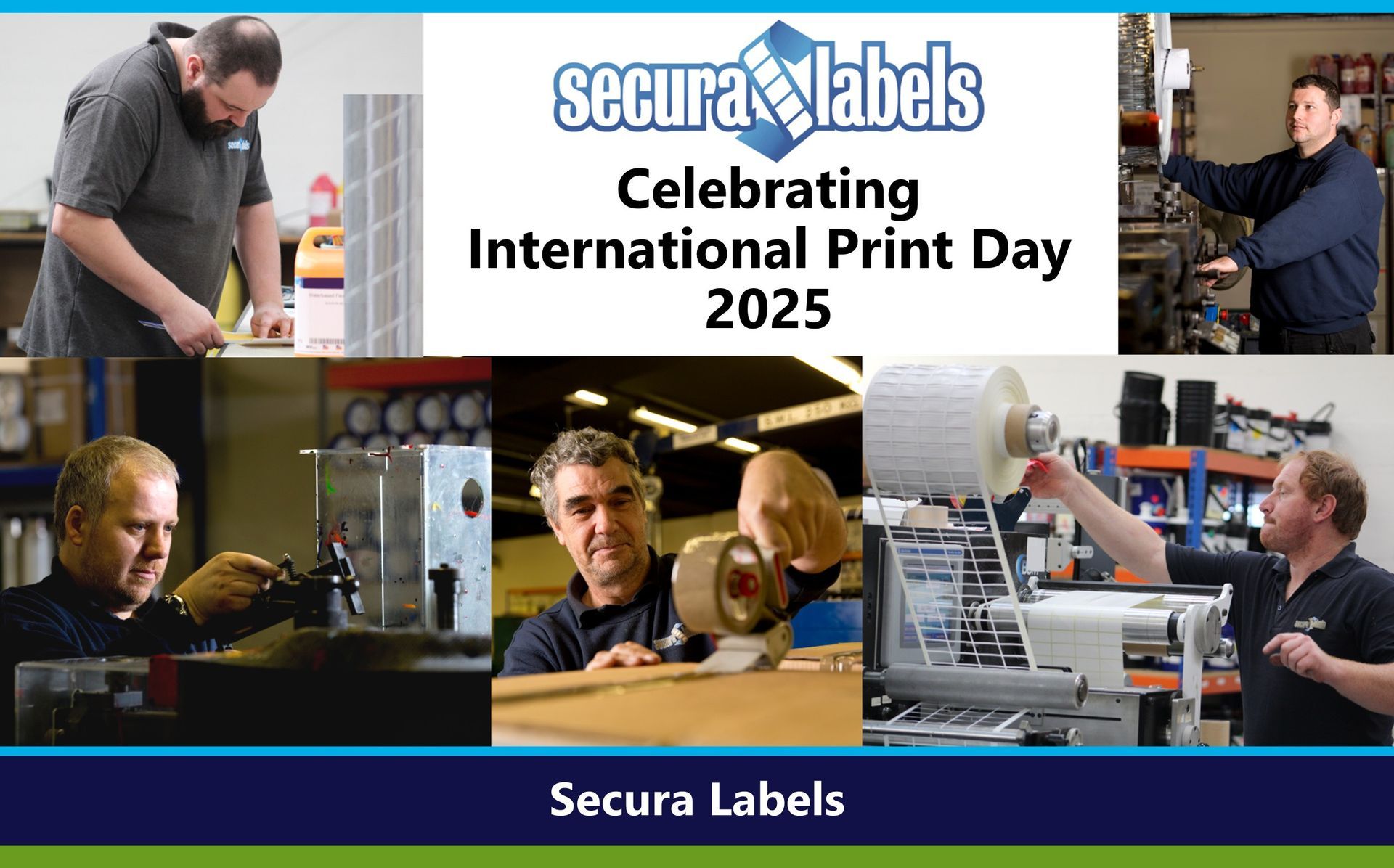

About Secura Labels

Secura Labels are a manufacturer of self-adhesive labels for all sectors including, but not limited to, logistics, food & beverage, pharmaceutical, NHS, security, packaging, electrical, construction and automotive.

We produce from small runs of 100s of labels, up to 1,000,000s and are proud to offer a trade service built on trust and the ability to understand the confidential nature of the work.

Founded in 1982, over 40 years ago, you can be assured of not only a great service but also expert advice, from the simplest of plain labels through to full colour process work, rolls, fan folded, sheets, tags or thermal transfer bureau work. We also supply thermal machines, ribbons and spares. We have many combinations of materials and adhesives on offer, but can also source more specialised products, so if there is anything specific you need, then do not hesitate to ask.

We can supply a wide range of sustainable materials, please contact us to find about more about this growing and ever changing material range, or find out more here.

If you would like further details on our services, or if you need to discuss a project you have in mind, please contact us.

Alternatively we can arrange a site visit to you to understand your needs better, or you can visit our

factory and offices in Measham, Derby. Call us today to discuss 01530 515 170

3,659

12,594

656,250

Cups of tea made